Our modern manufacturing and design industries rely heavily on surface manipulations to define not only performance, but also the aesthetic contribution of a product. In a myriad of choices readily available, the satin anodised finish has been a favourite among architects, engineers, and designers alike. Satin anodised finish goes beyond surface beauty to offer functional advantages, including a longer life and corrosion resistance, known to decorators as functional plus or practical plus, which accompany high aesthetic quality. In this article, the multidimensional significance of satin anodised finish is examined based on some focused discussions that emphasize the technical benefits, environmental impact, and changing role of satin anodised finish in different fields.

1.Understanding satin anodised finish

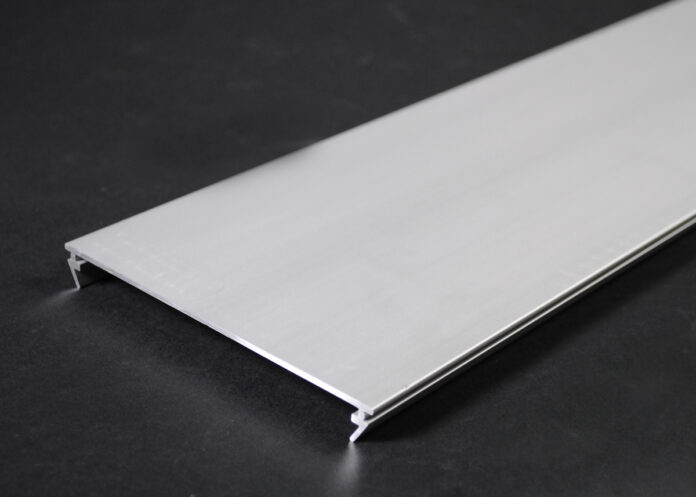

Satin anodised finish is a defined electrochemical process involving mostly aluminium surfaces, which converts the surface of the metal to a durable oxide layer, making it resistant to corrosion. The satin type of anodising is unlike the bright and matte types, which give an extreme sheen that can be either too fantastic or too flat. This delicate effect is achieved through highly controlled voltage, temperature and composition of the electrolyte during anodising. Consequently, the satin anodised finish can provide uniformity and consistency so that every treated object has a similar tone and the same texture. Moreover, due to being semi-lustrous, it has a humble charm that goes with a wide selection of applications that demand both subtle and graceful style and strength.

2.Higher durability and corrosion resistance

The key emphasis on the value of satin anodised finish is its addition to the base material qualities. Anodising is a technique where the inherent oxide film of aluminium is thickened, and this gives resistance to wear, abrasion and chemicals. This way, pieces that undergo satin anodised finishing become resistant to oxidation, pitting, and discolouration, regardless of harsh environmental factors. This can be passed on to life expectancy, reduced maintenance, and lower lifecycle costs. Satin anodised finishes happen mostly where design and life expectancy are important, like outdoor lights fixed, architectural claddings, and marine fittings. Satin anodised finishes bring in major improvement in the working efficiency in aggressive conditions, with protection of hidden metal structures.

3.Aesthetic Value and Adaptability

In addition to technical resiliency, satin anodised properties have an aesthetic quality that lends a sophisticated aesthetic to contemporary design. The gentle dimmed finishing spreads soft radiance and highlights the shape without distracting the plan’s attention. This subdued glow nicely complements a wide array of materials, including wood, glass, and concrete and allows the seamless adoption of the product in minimalistic interiors, modern buildings, and premium consumer goods. Additionally, the anodising can allow fine colouration by using integral colours – generally subdued shades, offering the designer a rich new palette that still has all the protective and corrosion resistance of the oxide layer. Satin anodised finishes provide an optimal combination of style and substance, whether used as a product housing, architectural framing or decorative feature.

4.Environmental and sustainability advantages

The satin anodised finish has an eco-friendly profile, which has become a key consideration in these material choices of the day. The energy consumed in the anodising process is comparatively small to that used in paint and powder coatings and does not contain any volatile organic compounds (VOCs). The oxide formed is also strongly bonded with the substrate, so there is no problem of peeling or flaking that results in particulate pollution. By the end of a product life, aluminium with a satin anodised finish can be recycled without separating the coatings, alleviating waste streams and saving resources. Manufacturers perpetuate the principles of circular economy by selecting satin anodised finish, thereby showing prudent resource and environmental management.

5.Stability and durability

Retention of a satin anodised finish is simple, and this has contributed to its extensive use. Since coated surfaces can flake off or need frequent retouch, the oxide layer of satin anodised finish is part of the metal and cannot be scratched or rubbed off. The technique is normally a mere soap and water clean, and thus there is no need to resort to a high-toxicity cleaner or carrier, which might strip it of protective features. The satin anodised coating retains the same appearance in ageing and in varied weather conditions with no fading or variable patina to impart. This low-maintenance property is advantageous to industries such as transportation and hospitality, where maintenance issues bearing on the solution directly impact operations and the satisfaction of users.

6.Industrial applications

The flexibility of satin anodised finishing has made it find its way into a very wide range of usages. It is applied in architecture as window frames, curtain walls, and external cladding, where it provides smooth forms and long service life. Consumer electronics manufacturers have used satanizing to provide an expensive appearance (and scratch resistance) with a satin finish on home appliances, smartphone frames and laptop covers. The automotive designers use satin anodised components in trim and interior accents as a tradeoff between design sophistication and practical toughness. Three leg fittings and satin anodised metal legs and fittings in the furniture area are a guarantee of long life as well as design consistency. In every industry, whether in subtle visual effects or technical assets, the necessity of this surface treatment is emphasized by an identical marriage of dynamics.

7.Effects on product and consumer perception

In competitive markets, products may be differentiated by the consumers riding on surface quality. The precision engineering and detailing are expressed by a satin anodised appearance that further validates a sense of quality and value. The physical smoothness of its surface and homogeneity of colour are indication of careful production that increases consumer confidence and readiness to spend money on high-priced products. Also, the long lifetime of satin anodised finish is transferred into visible confidence of product stability, implying less buyer apprehensions that the product may wear out or degrade quickly. As brands gain traction based on sustained high performance and sustainability factors, introducing satin anodised finishes into product offerings can serve to boost the brand’s position in the market and enhance customer retention.

8.Future trends and technological advances

The ongoing advancement in the technologies of anodising will increase the potential applications of the satin anodised finish. There is increasing fine control over oxide thickness and surface microstructure through improvements in electrolyte formulations and pulse-anodising techniques. Development into hybrid treatments seeks to combine satin anodised finish with nanocoatings, further adding properties of self-cleaning and anti-graffiti. Efforts are also being made to research additive manufacturing processes, which can be used to anodize complex structures in situ, thereby minimizing post-fabrication processes to create novel freedoms of design. With the rising popularity of sustainable manufacturing, the satin anodised finish will most probably change to adjust to more environmentally friendly and healthier standards without sacrificing its signature ability to balance beauty and strength.

Conclusion

The satin anodised finish is a particular niche where the visual aesthetics meet the protection of the material and the sustainability of the planet. From its basic functionality of lengthening the life span of components to its ability to improve the quality of aesthetics of the product, this surface treatment process has proven invaluable to a variety of industries today. Satin Anodised finishes support the design of high-quality products and structures through their ability to deliver long-lasting finishes with low maintenance requirements, their eco-friendly properties and their classic grace. With further improvements in technology and streamlining of the process of anodising, the significance of the satin anodised finish has only increased, so that the future of design can be as practical as it is pretty. JM Aluminium is one of the brands that are usually connected to the development of these anodising innovations.